On 12 May 2017, AVE 0043 from Sevilla Santa Justa to Barcelona Sants suffered a derailment at 268 km/h while passing through the Brazatortas loop on line 010, the Madrid-Seville high-speed line.

Despite the train’s high speed, no injuries or major material damage were reported. The design of the disc brake allowed the train, a 112 series train, to run 3.5 km derailed.

What happened in Brazatortas

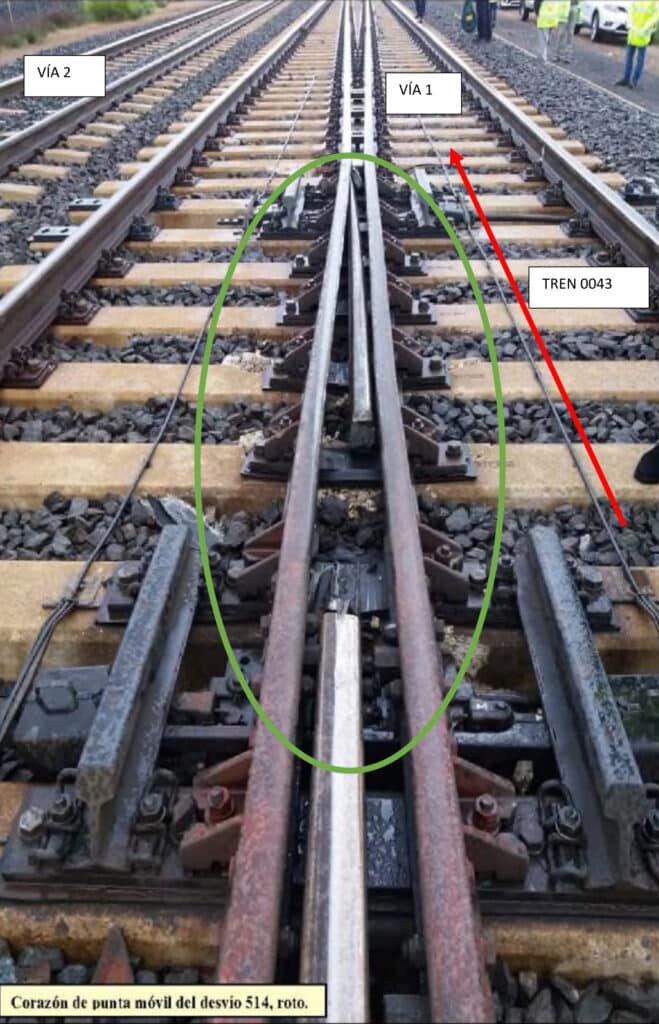

According to the CIAF report, on the morning of the accident, the train was running normally on track 1 when, as it crossed turnout 514, the movable end of the frog broke.

This fracture caused the number 8 wheel of the train to run off the track to the left. However, the left rail itself was wedged between the brake disc and the wheel, acting as a kind of guide. This circumstance prevented the train from moving sideways, keeping the vehicle aligned and avoiding a greater catastrophe.

This detail, highlighted in the report, was essential to avoid injury to passengers, as it allowed the train to maintain stability and stop without sudden movements or encroaching on the gauge of the adjacent track.

In fact, neither the driver nor the passengers perceived any impact before the emergency brake was activated, which facilitated an orderly and uneventful evacuation on board.

Causes of derailment

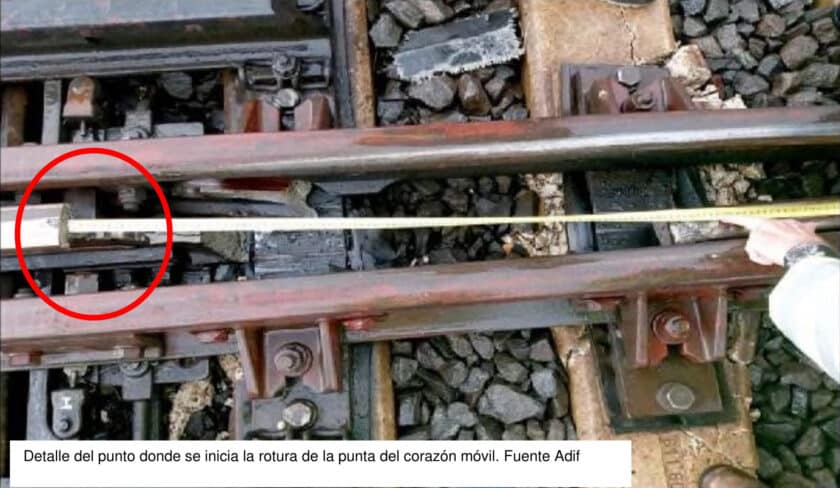

The CIAF investigation determined that the direct cause was an infrastructure failure: the transverse breakage of the movable end of the moveable point frog, attributed to the advance of internal micro-cracks originating from the rail manufacturing processes.

These micro-cracks, difficult to detect by conventional ultrasound and almost inherent to the rolling process, evolved by fatigue under the accumulation of structural stresses over 25 years of service. The part was original when the line was built.

The report further details underlying and system causes, noting that the maintenance of these turnouts and crossings did not include adequate internal monitoring techniques, nor was a lifecycle defined for such elements and their specific follow-up since their installation.

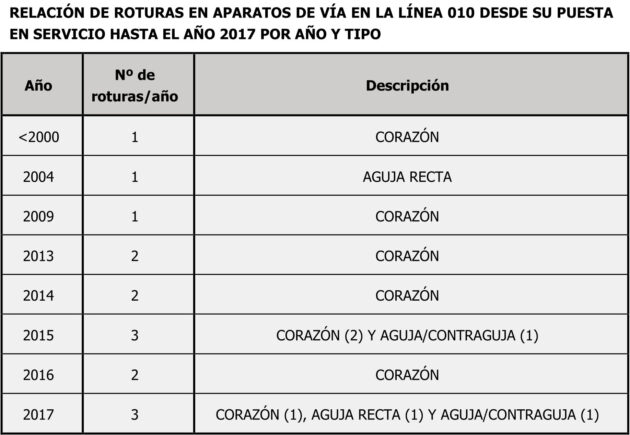

All this despite the fact that, as X user @unodelarenfe points out in a thread he posted in May, between 2013 and 2016 there were 8 frog breakages from the original 90s turnouts. A clear sign of fatigue.

Next to this table, CIAF indicates:

In 2013, the turnouts and crossings had been in service for 25 years, so it seems significant that from

onwards this type of occurrence is increasing. It should be considered that technical/scientific studies have not been carried out to know the behaviour of the elements of these turnouts and crossings subjected to daily traffic and to know their stress states, which could lead to detecting areas of accumulation of stresses that could cause the start of new cracks or cracks due to manufacturing defects and which, progressing through fatigue mechanisms, could cause the breakage of some of the elements of the turnouts and crossings.

CIAF actions and recommendations

Following the accident, the CIAF issued three key recommendations:

- To develop a methodology that allows in-depth knowledge of the internal evolution of the rails of the turnouts and crossings, incorporating appropriate techniques for detecting internal defects in preventive maintenance procedures on both the conventional and high-speed networks.

- Define life cycles for critical switchgear elements based on own and comparative experiences, ensuring replacement or reinforcement programmes before reaching the fatigue limit.

- To carry out detailed studies of the behaviour of turnouts and crossings as a function of their ageing and intensive use, to anticipate corrective measures for possible defects and failures, learning from national and international experience.

Immediate and medium-term consequences

The accident caused significant material damage to the train and, above all, to the infrastructure: breakage of the turnout, affected sleepers, damage to the ballast, broken rails and damage to the signalling installations along several kilometres.

In addition, the partial closure of the line and the speed limitations caused more than 4,900 minutes of accumulated delays on AVE and Avant trains. The impact on the service, however, was less than if this incident had occurred today, due to the lower number of trains and their lower demand at the time.

Adif replaces turnouts on high-speed lines to prevent this from happening again

Adif responded by intensifying manual inspections and scheduling advanced auscultation campaigns, using phased array technology. In addition, the infrastructure manager has since then been promoting an ambitious renewal plan for the affected track equipment, or those that could suffer from fatigue due to their use.

This accident highlighted the need for a more demanding and technified preventive management of the critical elements of the high-speed railway, marking a turning point in the policies of maintenance and control of the track in Spain.